CASE STUDY -1

1. Tiruppur Textile Effluent Management Project, Tiruppur

Client: Tiruppur Textile Dyeing Industries

Implementation Phase

TWIC assisted nine Common Effluent Treatment Plants in development of zero discharge solution for the bleaching and dying units in Tiruppur. The total effluent treatment capacity of these nine CETPs is 53,000 cum per day, forming the majority of the effluents generated in Tiruppur. The cost of this project was Rs.4200 million.

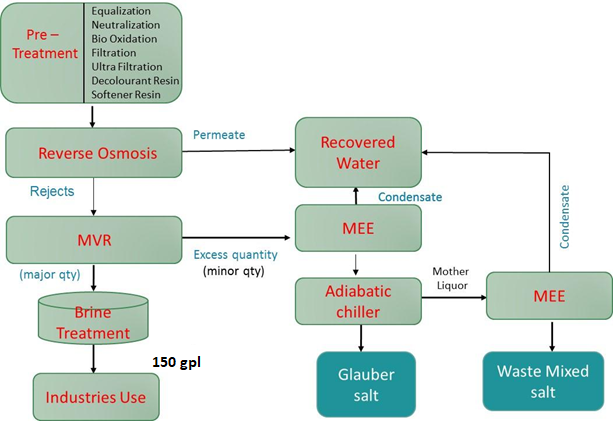

The scope of work undertaken by TWIC was preparation of detailed project reports, selection of technology and project specification, design engineering, procurement of contractor, arranging finance for the project was thereafter implemented supervision. The components of the ZLD CETP are Pipeline for effluent conveyance, Pre-treatment works, Reverse Osmosis plant, Evaporator plant, and Recovered water distribution system.

TWIC has also developed an alternate technology called “Treated Brine Reuse Technology” which substantially reduces the dependence on evaporator. This has been successfully demonstrated at Arulpuram CETP and is now being implemented in the remaining TWIC developed CETPs.

O&M phase

O&M services for Zero Liquid Discharge (ZLD) based Seven Common Effluent treatment plants with capacities ranging from 3 MLD to 11 MLD in Tiruppur textile cluster. The effluents from various industries are collected, metered, and conveyed to the Common Effluent Treatment Plant (CETP) for treatment and recovered water is distributed back to the industries for processing. These CETPs are equipped with Pre-treatment system (Biological Oxidation system based on Activated Sludge Process), Reverse Osmosis system and Mechanical Evaporator for RO reject handling.

TWIC has well qualified and experienced team of Managers, Engineers, Chemists, Operators and Technicians for monitoring the operation of the CETPs round the clock.

Process Scheme

2. Consultancy Services For Implementation Of The Integrated Wastewater Management (ZLD) For Tannery CETP

Pallavaram Tanners Industrial Effluent Treatment Company Ltd

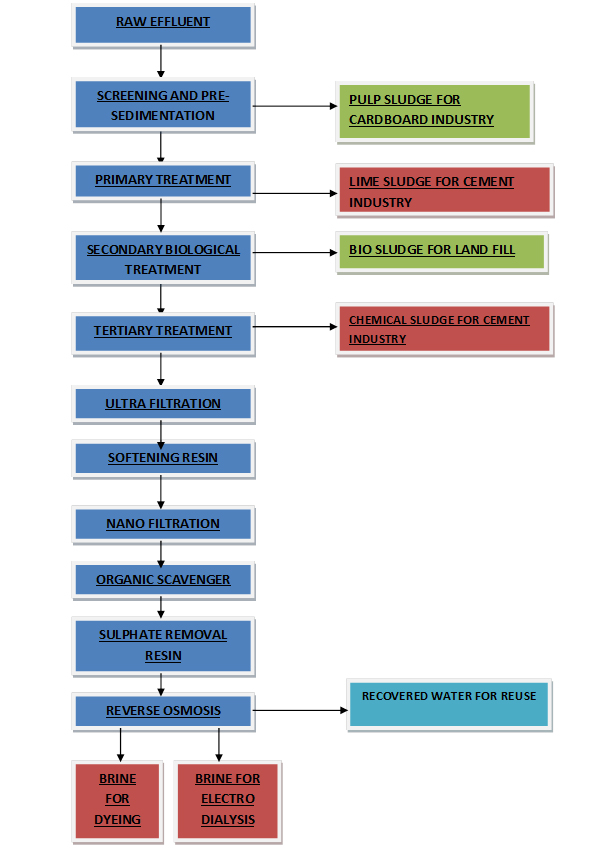

Owners Consultation Engineer for implementation of the integrated wastewater management project consists of the development of appropriate solutions to meet the Zero Liquid Discharge requirements for the Common Tannery Effluent Treatment plant of capacity 3 MLD.

TWIC had evaluated design and construction engineering documents monitored the project implementation works. This is to ensure the adequacy of treatment plant to treat a maximum of 3 MLD Tannery effluents. TWIC was also engaged by the CETP for providing “monitoring & feedback services” during the O&M of the plant by the EPC contractor.

Paper & Pulp Industry Effluent Treatment Project

| Project : | Technical and Commercial Feasibility for Development, Financing, Implementation and Operation of Zero Liquid Discharge Effluent Project for paper and Pulp effluent | ||

| Client: | Large Pulp & Papers Mill in South India | ||

| TWIC’s Role: | DPR Consultant & Technical evaluation study | ||

| Location/Cluster: | Tamilnadu | ||

| Environmental issues addressed: | To meet the Environmental norms as specified by TNPCB. | ||

| Capacity of Pilot plant: | 120 KLD | ||

| Next Steps/Further Business Scope | DPR Consultant & Role of PMA | ||

Process Scheme

| SL. No. | Description | Details |

| 1. | TWIC Role | Project Management Consultant |

| 2. | Project Name | Setting up of 10 MLD Zero Liquid Discharge based Common Effluent Treatment Plant for Textile Effluent |

| 3. | Beneficiary Name/ Project Location | M/s. Kakatiya Mega Textile Park, Warangal, Telangana |

| 4. | Name of the Client | Ministry of Textiles (MoT), Government of India under Integrated Processing Development Scheme (IPDS) |

| 5. | Approved Project Cost | Rs. 163.26 Crores. |

| 6. | Project Period | 2021 onwards |

| 7. | Description of actual services provided | Evaluation of the proposal and forward the same to Project Scrutiny Committee and recommendation to Project Appraisal Committee for final approval of Ministry of Textiles (MoT). Periodical monitoring of the Project implementation and submit the periodical reports to MoT with regard to the progress of the implementation works. Scrutiny of claims, including disbursements of utilization of funds, until the completion of the project. |

| SI. No. | Description | Details |

| 1. | TWIC Role | Project Management Consultant |

| 2. | Project Name | Upgradation of CETP capacity from 3.1 MLD to 8 MLD Zero Liquid Discharge based Common Effluent Treatment Plant for Textile Effluent. |

| 3. | Beneficiary Name / Project Location | M/s. NextGen Textile Park Private Limited, Sardar Samand Road, Pali, Rajasthan |

| 4. | Name of the Client | Ministry of Textiles (MoT), Government of India under Integrated Processing Development Scheme (IPDS) |

| 5. | Approved Project Cost | Rs. 129.42 Crores. |

| 6. | Project Period | 2021 onwards |

| 7. | Description of actual services provided | Evaluation of the proposal and forward the same to PSC and recommendation to Project Appraisal Committee for final approval of MoT, Periodical monitoring of the Project Implementation and submit the periodical reports to MoT with regard to the progress of the implementation works. Scrutiny of claims, including disbursements of utilization of funds, until the completion of the project. |

| Case Study: Consultancy services | |||

| SI. No. | Description | Details | |

| 1 | Project Name | Feasibility Report for setting up of Konabari Central Effluent Treatment Plant for Textile Dyeing Units in Konabari Cluster. | |

| 2 | Project Location | Konabari Cluster, Gazipur, Bangladesh. | |

| 3 | Name of the Client | International Finance Corporation (IFC) The World Bank Group (WBG), Dhaka, Bangladesh. | |

| 4 | Project Period | 2016-17 | |

| 5 | Designed Capacity of the proposed CETP | Zero Liquid Discharge (ZLD) based Central Effluent Treatment Plant (CETP) for Textile effluent in modules of 15 MLD expandable to a maximum of 60 MLD. The number of streams or modules (of 15 MLD each) proposed to be implemented can be based on the actual number of participants in the project and demand of the shareholders of the CETP company.

ZLD – ZWS Technology: – Zero Liquid Discharge (ZLD) with Zero Waste Salt (ZWS) generation with NF and MEE |

|

| 6 | Unique Features of the Project |

|

|

| Estimated Project Cost for one module of 15 MLD |

Phase – I (Till MBR): Million USD 16.20 Phase – II (Add-on ZLD): Million USD 31.55 |

||

| SI.No | Description | Details |

| 1 | Project Name | Implementation of 20 MLD CETP including Collection & Conveyance. Chrome Recovery and Zero Liquid Discharge based Demonstrative Tannery Wastewater Treatment system for 200KLD capacity (Pilot Plant) at Jajmau, Kanpur, Uttar Pradesh |

| 2 | Client | National Mission for Clean Ganga, New Delhi, India.

(Registered Society Under Ministry of Water Resources, River Development & Ganga Rejuvenation, Government of India) |

| 3 | TWIC’s Role | Project Engineer |

| 4 | Location/Cluster | Jajmau, Kanpur, Uttar Pradesh |

| 5 | Scope of Work | 1. Implementation of Pre-treatment unit at 380 individual Tannery Units.

2. Implementation of Collection and Conveyance system and pumping station 3. Implementation of 300KLD X 3 module capacity of Common Chrome Recovery Plant and 20 MLD Capacity CETP up to Ultrafiltration and Sewage dilution facilities. 4. Implementation of 200 KLD ZLD pilot plant. |

| 6 | Environmental issues addressed | To meet the Environmental norms as specified by Government of Uttar Pradesh |

| 7 | Capacity of Plant | 20 MLD |

| 8 | Present Situation | Construction under Progress |